Especially freight traffic depends on efficient and sustainable means of transport and processes. Freight transport is becoming increasingly important, with information exchange and communication playing a prominent role. The holistic view of logistics structures and processes and their challenges is also getting more and more relevant.

Intelligent freight transport concepts enable self-controlled traffic using innovative and forward-looking technologies. By transferring innovative technologies and principles of Industry 4.0 to off-site freight transport, completely new possibilities for process control and optimization are opening up to the actors along the transport chain. In this way, players in the transport sector can work together effectively and increase effectiveness and efficiency. The Commercial Transport WG offers research and consulting services in six relevant areas:

- Transport Logistics 4.0 / Freight Mobility 4.0

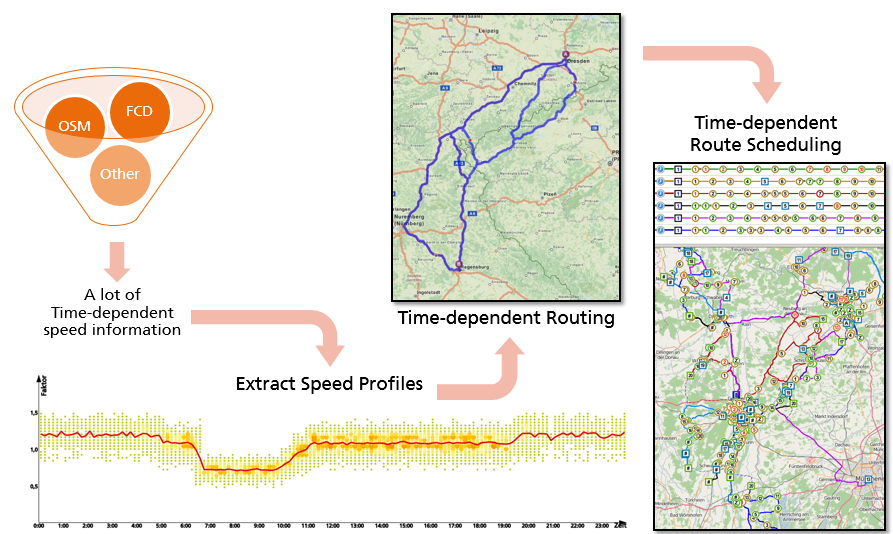

- Planning & optimization of transports

- Synchromodal freight transport

- Digitization / IoT in transport

- Process data analysis (city) logistics

- Digital CT terminal of the future

Fraunhofer-Allianz Verkehr

Fraunhofer-Allianz Verkehr