Fraunhofer IDMT in Oldenburg develops acoustic sensor technology and algorithms for quality assurance in automobile production, test drives, test bays and ongoing vehicle operation. With the help of intelligent condition monitoring of equipment and processes via structure-borne and airborne sound, faults and deviations can be detected at an early stage and without physical or visual contact. In addition, the acoustic monitoring systems can detect damage before it occurs. This avoids downtimes and makes it easier to plan maintenance work (predictive maintenance). Signal pre-processing methods reduce application-specific disturbance variables in Fraunhofer IDMT’s developments. For reliable real-time monitoring at all levels of modern system architectures, we develop innovative AI methods and make the data packets to be transmitted significantly smaller. Our services range from in-line and end-of-line monitoring to monitoring during driving (»The Hearing Car«).

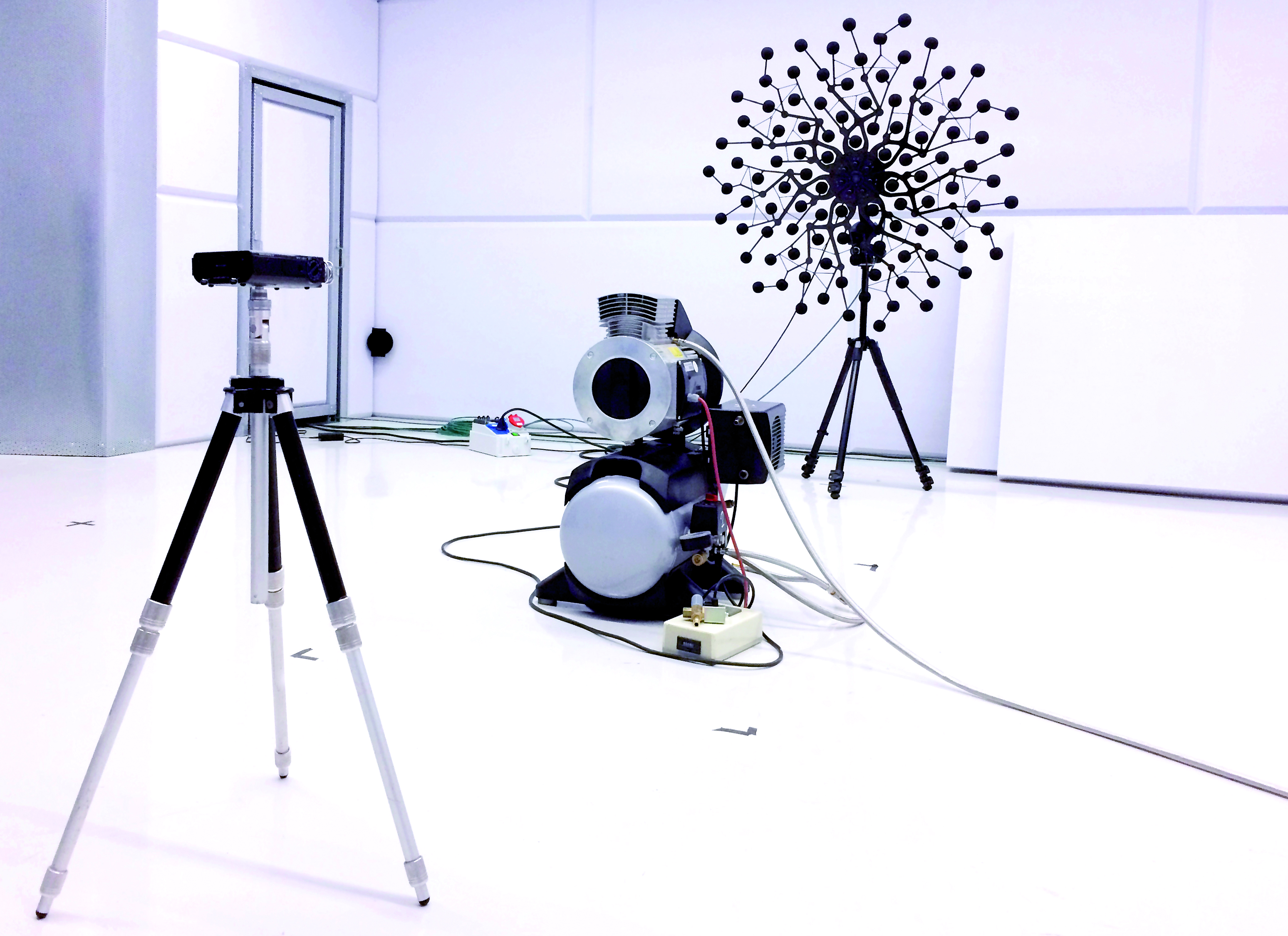

Specifically, we focus, among others, on the reliable clicking into place of plug connections: The sensors detect deviations in the sound, for example when a »click« is triggered as plug connections engage. In another project, we use intelligent audio technology and innovative AI methods to detect leakages in pneumatic actuators. But our service portfolio also includes solutions for driving, such as recognition of the road surface or different scenarios. From scene classification, for example recognition of an approaching ambulance with its siren switched on, we can derive intelligent automatisms, such as forming an emergency lane.

Fraunhofer-Allianz Verkehr

Fraunhofer-Allianz Verkehr