The size and complexity as well as the unique character of maritime products present shipyards and suppliers in shipbuilding with great challenges. The aim of the research and development activities in this context is to develop holistic solutions that enable maritime customers to manufacture efficiently, cost-effectively and to a high standard of quality. Components of the portfolio are:

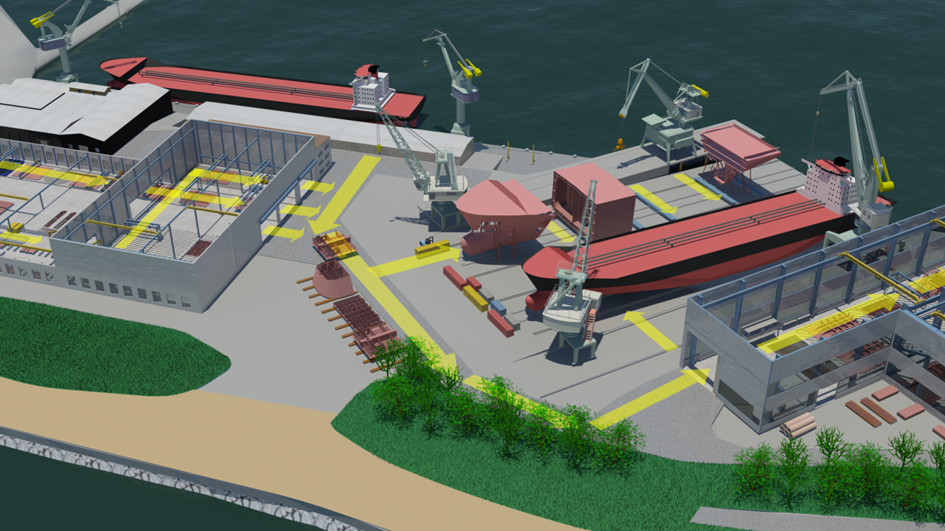

Planning and development of shipbuilding production facilities as well as the design, development and implementation of integrated digital process chains over the entire product life cycle

Development of efficient automation concepts and novel design approaches (e.g. lightweight construction, optimisation of noise and vibration behaviour)

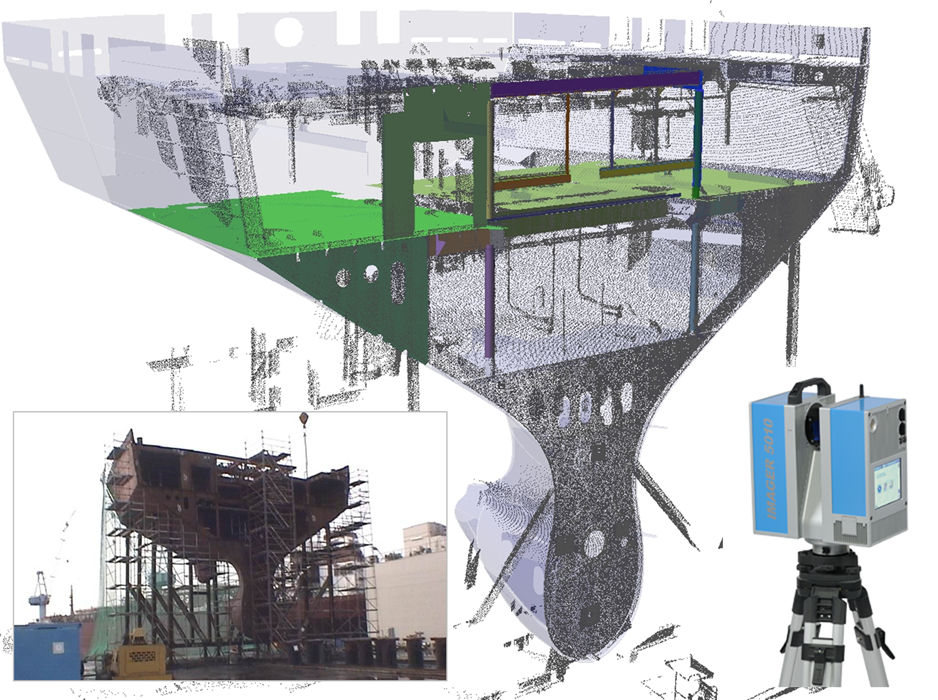

Innovative use of the latest technologies such as the development and qualification of new types of joining technologies (e.g. welding, gluing, mechanical joining) or quality assurance through high-precision geometric measurement of large components

Fraunhofer-Allianz Verkehr

Fraunhofer-Allianz Verkehr